Individual consulting & service

The requirements for cleanroom environments and cleanliness conditions are constantly increasing. The direct and indirect influence on product purity are playing an increasingly important role. Therefore, many factors must be taken into account during planning. Regardless of whether pharmaceutical, medical technology, semiconductor or pure electronics products are produced. Industries such as the automotive industry are also now increasingly using controlled environmental conditions to increase product quality. Risks must therefore be identified and complexity minimized, starting with the manufacturing steps themselves, the infrastructure, the testing procedures up to the media and materials used and their surface properties in connection with direct or indirect product contact. In addition, processes must be defined and validated, equipment and manufacturing facilities must be qualified in order to achieve the desired product quality and to reproduce it on a permanent basis.

Medical Technology

Medical technology as an engineering discipline with the aim of developing finished products, devices and procedures for the prevention, diagnosis and therapy of diseases.

Pharmaceutical industry

Development and production of drugs with the aim of a pharmacological, immunological or metabolic effect

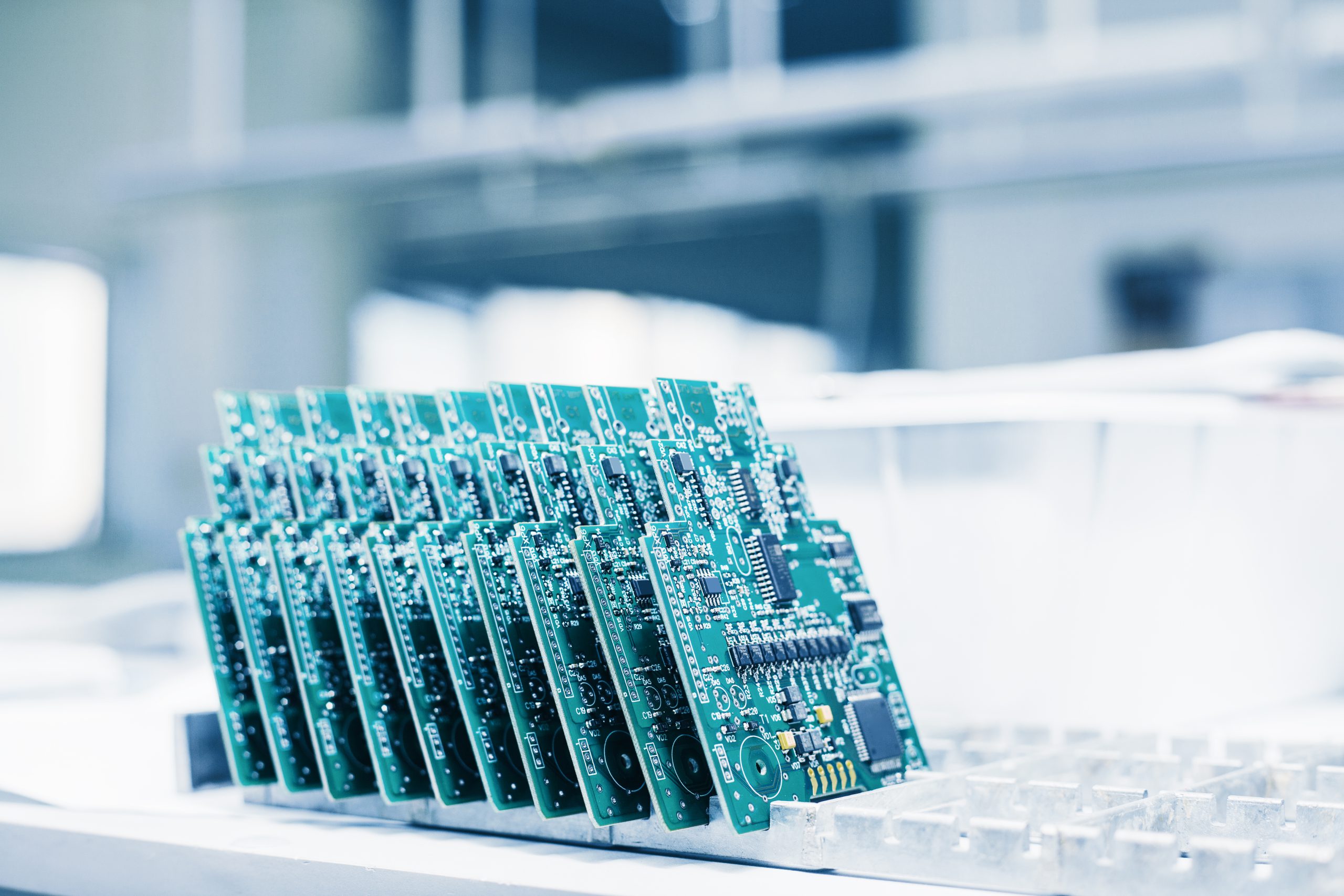

Electronics industry

Manufacturing and assembly in plant engineering, automation, batteries, consumer electronics, electric vehicles, electrical power engineering, cables, and more.

Semiconductor industry

Design, development and technical production of products such as components or assemblies based on semiconductor materials